Western Sahara Offshore photovoltaic

Category:

Western SaharaOffshore steel platform

Product Description

External anti-corrosion type

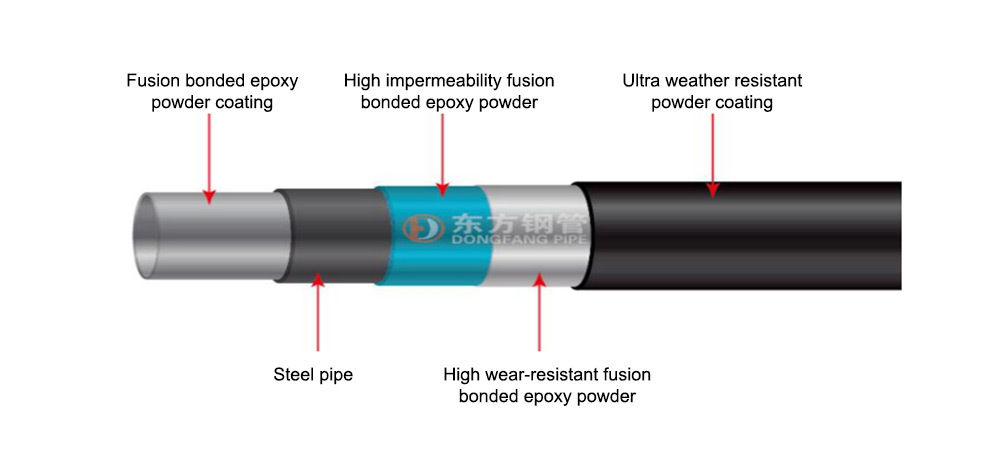

Based on the characteristics of the corrosive environment, a double-layer powder coating structure with high penetration resistance and chisel resistance is determined to be used for the anti-corrosion of the outer wall.

Underwater part: The primer is made of modified epoxy powder with ultra-high cross-linking density; The surface coating is made of high scratch resistant composite epoxy powder.

Water part: The primer is made of modified epoxy powder with ultra-high cross-linking density; The surface coating is made of ultra weather resistant fluorocarbon powder.

Tidal range section: Using a three-layer structure of mineral fat coating material (patented by Academician Hou Baorong).

Internal anti-corrosion type

The inner layer requires excellent anti-corrosion and scratch resistance performance of the coating, and it is determined that the internal anti-corrosion is the same as the outer wall anti-corrosion surface coating.

Inner and outer layer joint repair

Using polymer macromolecules with high resistance to penetration and chiseling composite coating (multi-layer) as a specialized patching material.

Product Features

1.The integration of steel pipe and anti-corrosion, with controllable quality, each product has its own identification code from raw materials to finished products, and the product is traceable, reflecting the company's confidence and strength in product quality.

2.The outer wall adopts a new material with a bottom layer ultra-high adhesion and high anti-corrosion (cathodic stripping) formula, and a surface layer ultra-weather resistance and high erosion resistance formula, which is particularly suitable for marine anti-corrosion environments.

3.The inner and outer wall coatings have no leakage points, do not require additional cathodic protection measures, have low engineering cost, and are environmentally friendly, eliminating the heavy metal zinc caused by sacrificial anode protection from causing ecological damage to the ocean.

4.The thickened coating on the outer wall of the tidal range and splash zone, combined with excellent wear resistance, can meet the requirements of erosion resistance.

Case Presentation